Injection via needle and syringe is the quickest way to transfuse medicine and fluids into one's body, but not everyone is a fan of shots. Many people have a fear of needles -- "aichmophobia," it's called -- while others frequently self-inject and simply don't want to inject themselves all the time. While completely understandable, it's a dilemma that scientists from the Massachusetts Institute of Technology are setting out to solve.

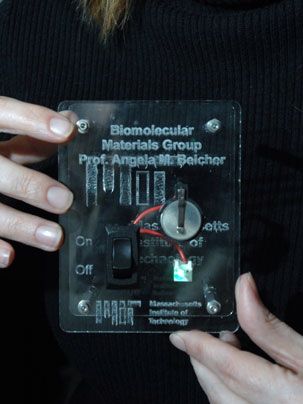

MIT researchers unveiled a prototype device on Thursday that uses a new way to administer drugs, replacing the common needle with a tiny, highly-controllable jet injector, which sends a high-pressured stream directly into the skin. The jet can both inject into and aspirate from tissue, and the device is controlled via a computer interface, which can control the volume of the drug delivery, and the velocity at which it moves.

"We were able to fire the drug out at almost the speed of sound if we need to -- the speed of sound in air is about 340 meters per second," said professor Ian Hunter, who runs the bioinstrumentation lab at MIT's Department of Mechanical Engineering. "It's capable of pressurizing the drug up to 100 megapascales (MPas), and we can do that in under a millisecond."

Hunter worked on this project with MIT colleague Dr. Catherine Hogan, as well as a handful of "talented post-docs and others in the lab." Hogan explains how the device works: "There's a magnet in the center of our jet injector that's surrounded by a coil of wire, and when we apply a current to the coil, we create a Lorentz Force that pushes this piston, which forces the drug out of the ampoule," Hogan said. "This gives us a tremendous amount of control depending on how much current we put in, so that we can successfully deliver a wide variety of volumes of drug at a wide variety of velocities with a very low degree of error, something a needle can't do."

There are other advantages of MIT's jet injector over needles: For instance, doctors would be able to control the speed of the injection throughout the duration of the delivery, so it can be quickened or slowed depending on the drug and the patient. "We can also change the velocity over the course of a single injection, so it breaches the skin at one velocity, and then disperses the drug at another," Hogan said. "We accelerate the coil to the desired speed, hold it there for a defined time, and the decelerate to a lower velocity to disperse and absorb the drug into the tissue."

But besides giving doctors better control over injections, the best part of this technology is that it is virtually painless -- in fact, patients won't feel much of anything at all. Hunter explains why: "The drug comes out of this fine jet -- about the same diameter as a mosquito proboscis -- and as many of you know, you don't feel when a mosquito inserts its proboscis into your skin because it's so very narrow," Hunter said. "Our jet is of a similar diameter."

The thinness of the jet makes it perfect for some of the most scariest procedures that involve needles, which is why MIT's research team is developing other ways to utilize this technology. "We've also developed this device so it can for delivery of drugs right through the eye into the retina," Hunter said. "We've succeeded in delivering drugs through the tympanic membrane in your ear, so that we can deliver drugs to the middle and inner ear. And we've also done something that we think is pretty cool: We can take a drug in powdered form, put it in this device, and the device -- because of its very, very fast response -- is able to vibrate that powder so it behaves like a liquid, and then we inject it into tissue as though it was a liquid, even though it's a powder."

Even though this is not the first attempt to create a painless needle, or a new take on the needle, MIT believes this technology is superior with its highly-controlled system for limiting the injection velocity and dosage, but also it's ability to bring ease to patients with needle phobias. An instantaneous, painless injection beats a stinging shot any day of the week.

MIT researchers unveiled a prototype device on Thursday that uses a new way to administer drugs, replacing the common needle with a tiny, highly-controllable jet injector, which sends a high-pressured stream directly into the skin. The jet can both inject into and aspirate from tissue, and the device is controlled via a computer interface, which can control the volume of the drug delivery, and the velocity at which it moves.

"We were able to fire the drug out at almost the speed of sound if we need to -- the speed of sound in air is about 340 meters per second," said professor Ian Hunter, who runs the bioinstrumentation lab at MIT's Department of Mechanical Engineering. "It's capable of pressurizing the drug up to 100 megapascales (MPas), and we can do that in under a millisecond."

Hunter worked on this project with MIT colleague Dr. Catherine Hogan, as well as a handful of "talented post-docs and others in the lab." Hogan explains how the device works: "There's a magnet in the center of our jet injector that's surrounded by a coil of wire, and when we apply a current to the coil, we create a Lorentz Force that pushes this piston, which forces the drug out of the ampoule," Hogan said. "This gives us a tremendous amount of control depending on how much current we put in, so that we can successfully deliver a wide variety of volumes of drug at a wide variety of velocities with a very low degree of error, something a needle can't do."

There are other advantages of MIT's jet injector over needles: For instance, doctors would be able to control the speed of the injection throughout the duration of the delivery, so it can be quickened or slowed depending on the drug and the patient. "We can also change the velocity over the course of a single injection, so it breaches the skin at one velocity, and then disperses the drug at another," Hogan said. "We accelerate the coil to the desired speed, hold it there for a defined time, and the decelerate to a lower velocity to disperse and absorb the drug into the tissue."

But besides giving doctors better control over injections, the best part of this technology is that it is virtually painless -- in fact, patients won't feel much of anything at all. Hunter explains why: "The drug comes out of this fine jet -- about the same diameter as a mosquito proboscis -- and as many of you know, you don't feel when a mosquito inserts its proboscis into your skin because it's so very narrow," Hunter said. "Our jet is of a similar diameter."

The thinness of the jet makes it perfect for some of the most scariest procedures that involve needles, which is why MIT's research team is developing other ways to utilize this technology. "We've also developed this device so it can for delivery of drugs right through the eye into the retina," Hunter said. "We've succeeded in delivering drugs through the tympanic membrane in your ear, so that we can deliver drugs to the middle and inner ear. And we've also done something that we think is pretty cool: We can take a drug in powdered form, put it in this device, and the device -- because of its very, very fast response -- is able to vibrate that powder so it behaves like a liquid, and then we inject it into tissue as though it was a liquid, even though it's a powder."

Even though this is not the first attempt to create a painless needle, or a new take on the needle, MIT believes this technology is superior with its highly-controlled system for limiting the injection velocity and dosage, but also it's ability to bring ease to patients with needle phobias. An instantaneous, painless injection beats a stinging shot any day of the week.